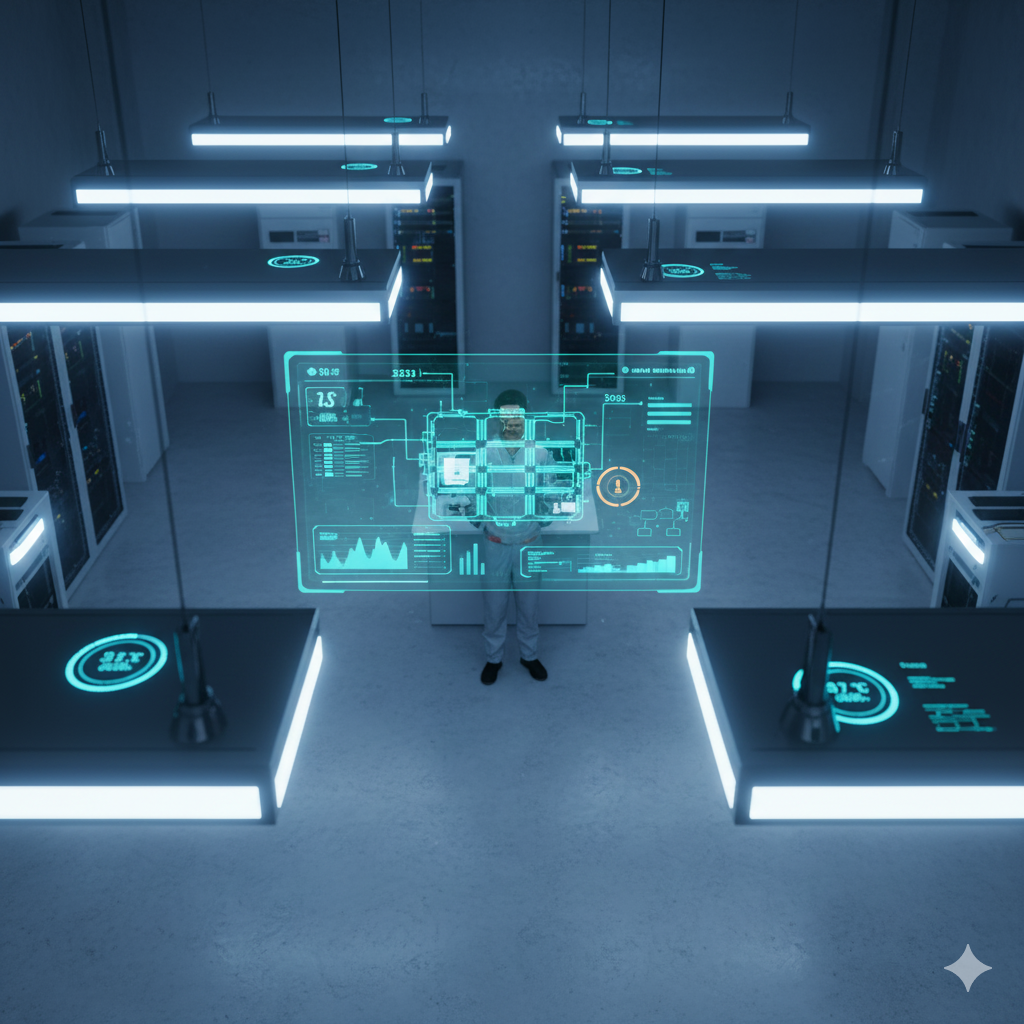

Transform your facility’s lighting into smart, connected assets that enhance industrial excellence while delivering substantial energy savings. Evoluzn’s ILMS retrofits your existing fixtures with cutting-edge controllers integrated with real-time sensors for occupancy, daylight, lux, fixture temperature, and power consumption. This intelligent system dynamically optimizes illumination and operational efficiency without compromising safety or lighting quality.

Unlock up to 75% energy savings while boosting productivity, safety, and operational excellence in your facility with Evoluzn’s advanced IIoT-enabled Intelligent Lighting. Modernize your lighting ecosystem for measurable results, streamlined maintenance, and proven sustainability. Contact us today for a tailored consultation and see how smart lighting can transform your operations.

Retrofitting with Evoluzn’s ILMS reduces 50% of capital costs compared to purchasing fully automated lights upfront and also preserves existing wiring and reduces costs by up to 40%. Lighting zones adapt dynamically with ML-powered occupancy sensors setting schedules and lux thresholds, including randomized “presence” functions ideal for security in warehouses and stockrooms. Edge computing delivers rapid health monitoring and predictive insights in real time, reducing manual maintenance and ensuring uninterrupted, optimally lit operations.